‘E’ Approved Harness Fitting

Fitting

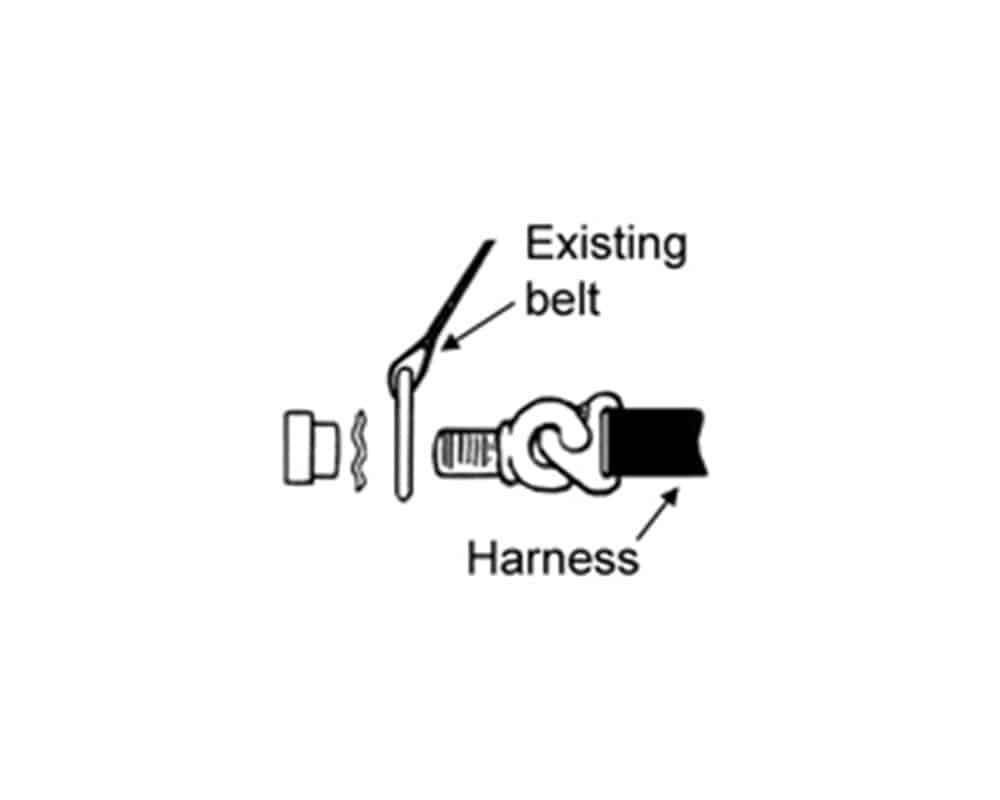

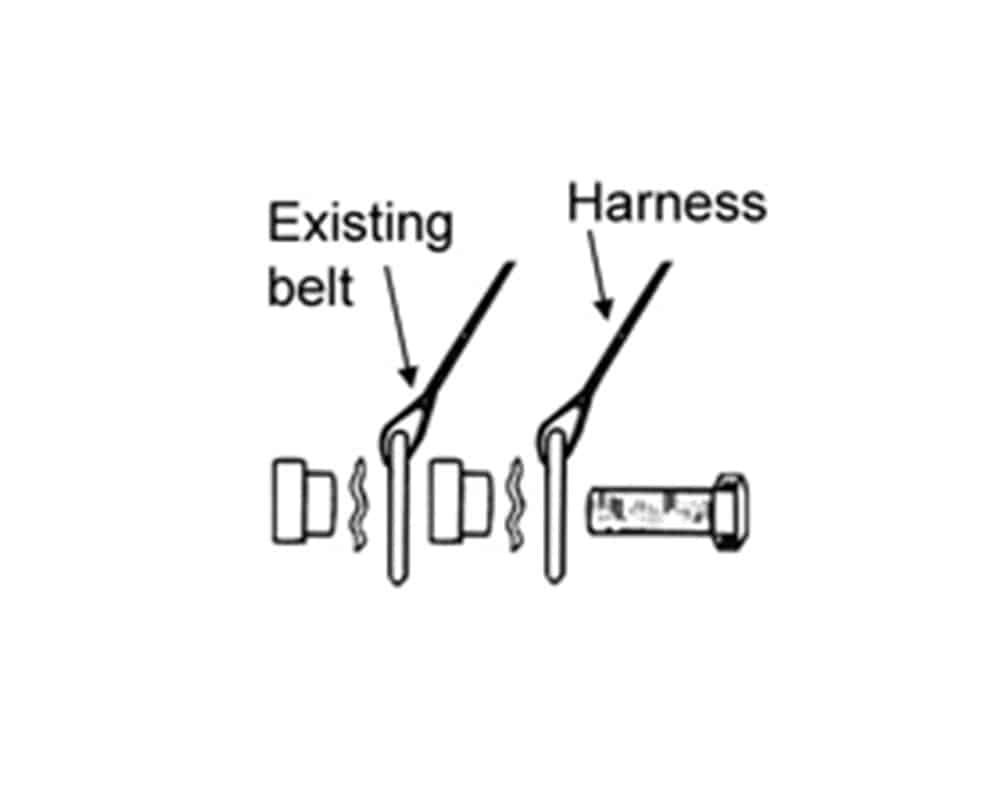

Locate anchorage points in car. The front and rear Lap anchorage points for the existing belt can normally be utilised.

Where anchorage points are not available these can be fabricated through the vehicle metal structure by drilling a 7/16” (11.5mm) hole.

Before drilling holes check suitability of load bearing bodywork. Allow clearance for wiring, pipes, tanks and cables etc.

The area must be of sound structure with no serious corrosion, distortion or fractures within 30cms of the anchorage point. We recommend reinforcing the structure around the hole.

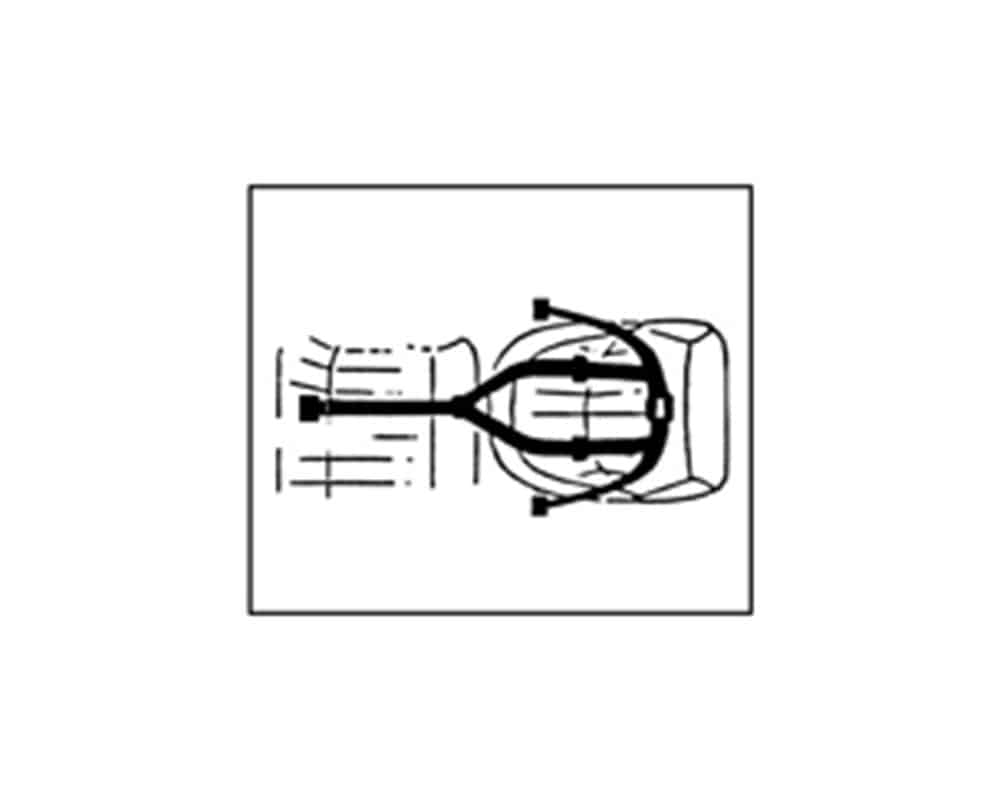

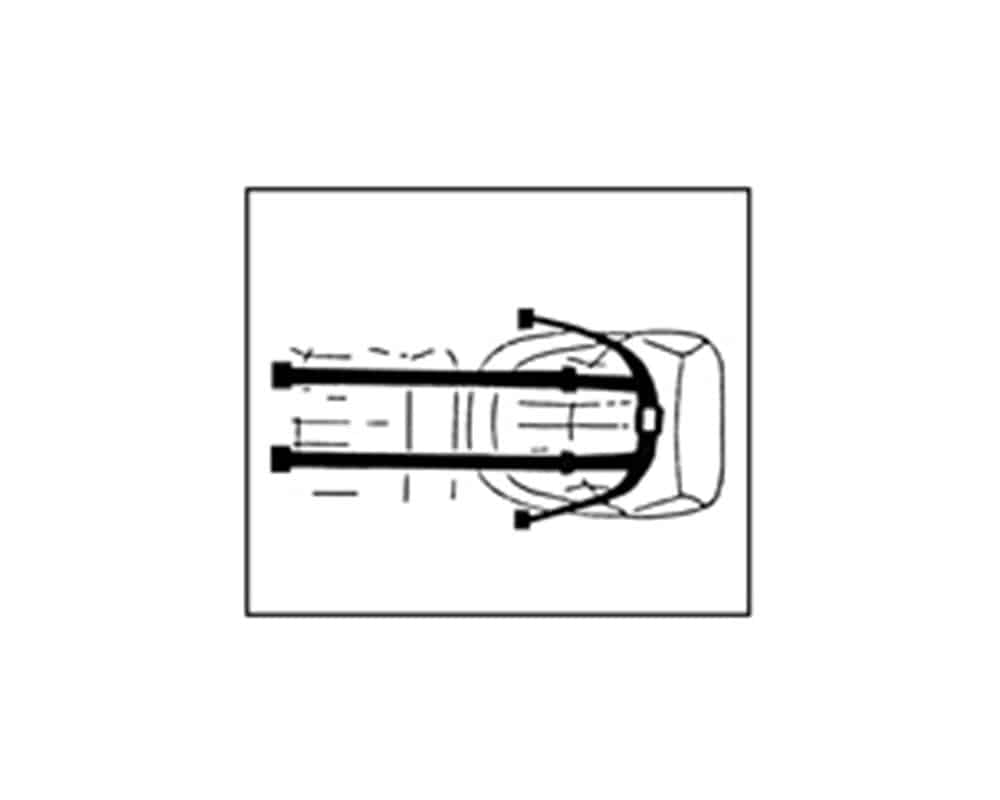

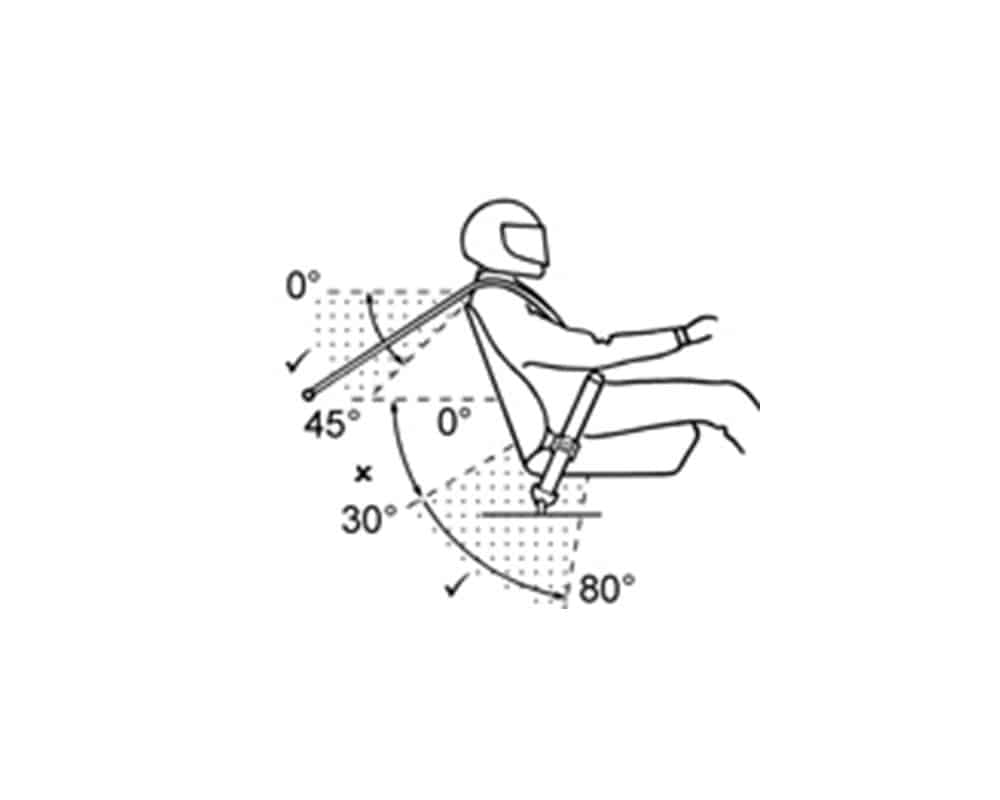

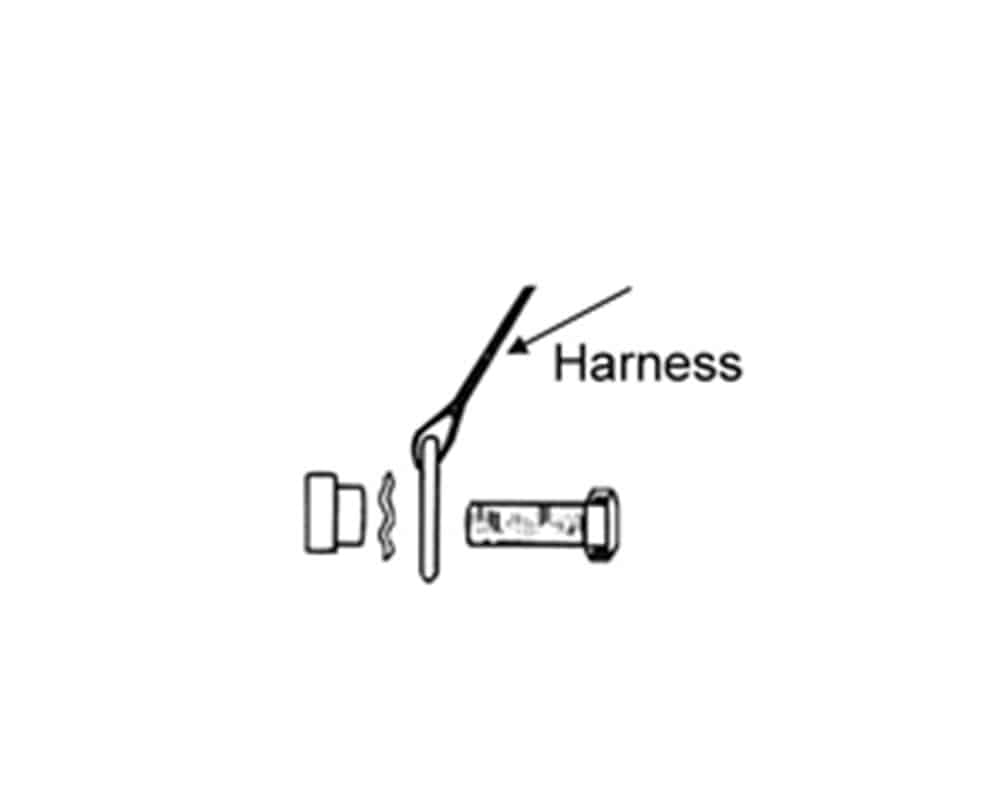

Anchorage Diagrams

Install Harness as shown referring to appropriate anchorage diagrams.

Adjust Harness to suit installation ensuring: a) The lap belt passes across the lap with the buckle centrally positioned. b) Shoulder belts pass across the centre of shoulders.

Adjusting

Tighten lap belt fully before adjusting shoulder belts

To tighten (shorten) the harness pull tail of webbing through adjusters until required length is reached.

To loosen (lengthen) the harness tilt the adjusters be means of the grip and slide it along until the required length is reached.

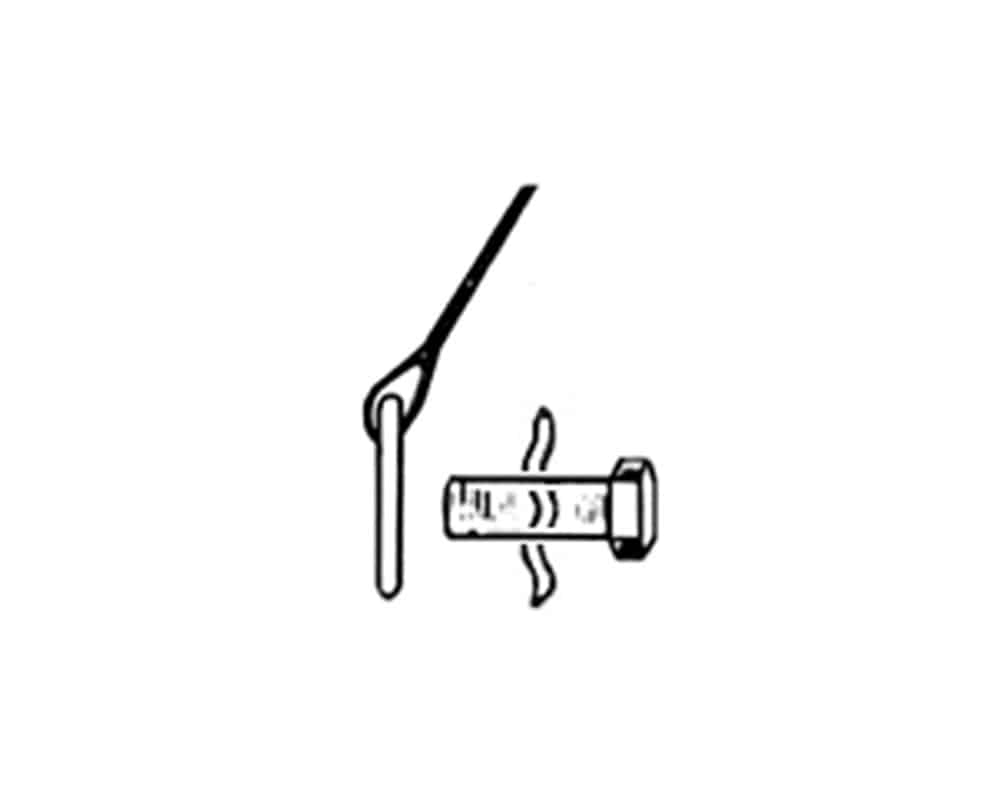

On snap hook anchorage points with bar adjusters - feed webbing through bars.

Users and Maintenance Instructions

FASTENING THE HARNESS: Insert tongue(s) into buckle. A positive locking ‘click’ indicates assembly.

RELEASING THE HARNESS: Press the red release button and the tongue will be released.

IMPORTANT

- The harness is designed to be used by only one person.

- It is important to wear the harness on each journey.

- The harness is intended for use by occupants of adult build.

- The harness should be adjusted and used in accordance with these instructions. No excessive slackness should be present.

- Avoid twisting webbing and ensure that snap hooks are correctly located in the eye bolts.

- To avoid damage ensure the harness is stored clear of doors, seat runners etc.

- Webbing must not be allowed to chafe against sharp edges on seat or bodywork.

- Harnesses that have been cut, frayed, damaged or stressed through impact should be replaced. After impact, anchorages should also be checked.

- Regular inspection of the harness is recommended.

- To clean webbing use warm soapy water only. Do not use chemical cleaners, bleach or dye under any circumstances.

- Contamination with petrol, grease and acid will be detrimental.